Design

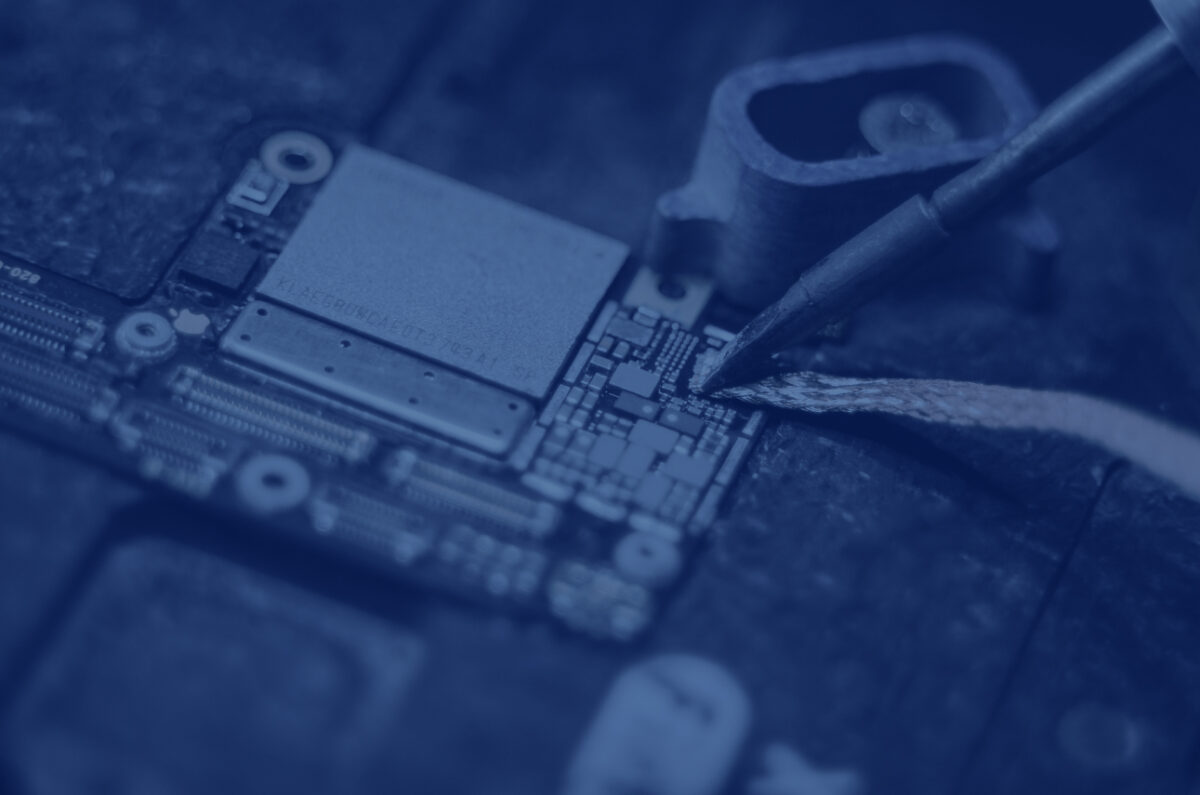

Design of electronic systems

With a forward-looking approach, SEIA Electronique invests in research and development through its integrated design office.

TAILOR MADE

We can optimize your electronic production system on the basis of a detailed specification.

RELIABLE

Our electronic equipment, which follows a rigorous and transparent design process, is guaranteed for up to two years

APPROPRIATE

We deliver a comprehensive and high-performance service, which brings your development projects to life.

ECO-FRIENDLY

We contribute to the extension of the service life of your entire production line.

DO YOU HAVE PLANS FOR THE OPTIMIZATION OF YOUR MACHINES?

Electronic design is critical to the industrial sector. SEIA Electronique is an experienced partner, if you have plans to invest in the enhancement of your competitiveness by optimizing your production capacities.

Working hand in hand, on the basis of a detailed specification, we can undertake the design analysis of any electronic system which is susceptible to obsolescence or the deterioration of electronic components, or of a production facility which is in need of general optimization. SEIA Electronique always have a multitude of solutions available, so that you are never left at a standstill.

Do we provide a comprehensive range of electronic repair services?

For the maintenance in operational condition (MOC) of your production facilities at all times

Sales & Purchases

Our stock of new or reconditioned components, which is supplied by our arrangement for the buyback of electronics from yourselves, provides an alternative to repairs.

Maintenance

We manage the obsolescence of your production line through the deployment of preventive and curative maintenance.

CLONING

With or without a circuit layout diagram, we can replicate the industrial electronic circuit boards which are essential to your production facility.

REPAIRS

We undertake operations in our workshops or on-site on any type of industrial electronic equipment, of whatever technology or any brand.

Specification

process

SPECIFICATION

For the definition of requirements and specifications

FEASIBILITY STUDY

For small and medium-sized production series

PRODUCTION OF A PROTOTYPE

On the basis of a circuit diagram, or from A to Z

TEST PHASE

For verification, adjustment and validation

LAUNCH OF PRODUCTION

And delivery of production series

Q&A on SEIA Electronics

How does the pick-up process work?

How can the progress of your requests be tracked?

The MySEIA client space is available for the provision of real-time information on the state of progress of responses.

You can also use this client space to consult your documents, confirm quotations, or use our live chat facility to talk directly to our staff teams, if you require any information.

FEEDBACK FROM OUR CLIENTS

Very good response for the repair of an electronic circuit board – out of service at 9 a.m. and repaired by 2 p.m.. Thank you again.

Highly professional, with a choice of high-quality components, and good advice. I would recommend them for any electronic repairs.

Very professional and a choice of quality parts with good advice ! I recommend them for all electronic repairs !

THEY PUT THEIR TRUST IN US